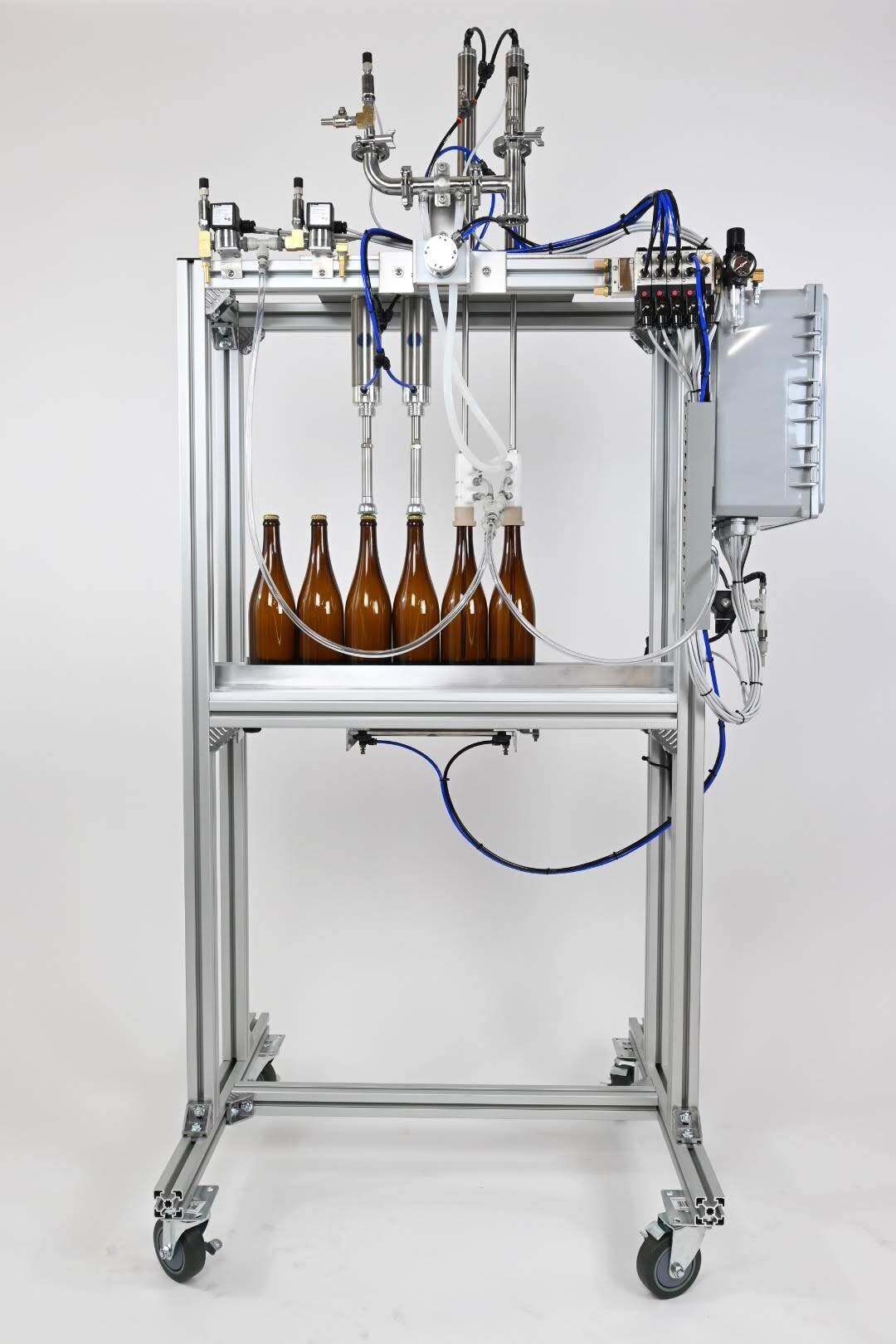

2 & 4 Head Bottle Fillers & Capper Starting at $8500

Our innovative counter pressure bottle fillers are extremely durable and offer the most flexibility among any other bottle filler on the market. Manufactured using cutting-edge technology and only the best-quality materials, our systems are guaranteed to meet each of your craft beverage bottling needs. Our counter pressure bottle filler machines come second to none. Uniquely designed to fill and cap any size bottle on the same platform, with minimal change over parts. This filler is powered by 110v/220v AC and compressed air. We understand how important your craft beverage operations are, whether you’re just starting out or are already distributing your products. That’s why our top-grade counter pressure bottle filler machines are engineered with a sturdy base, making mobility easier.

2 Head Filler Technical Specs & Pricing

Photo & Video of 2 Head Fillers

4 Head Filler TECHNICAL Specs & Pricing

View Video of 4 Head Fillers

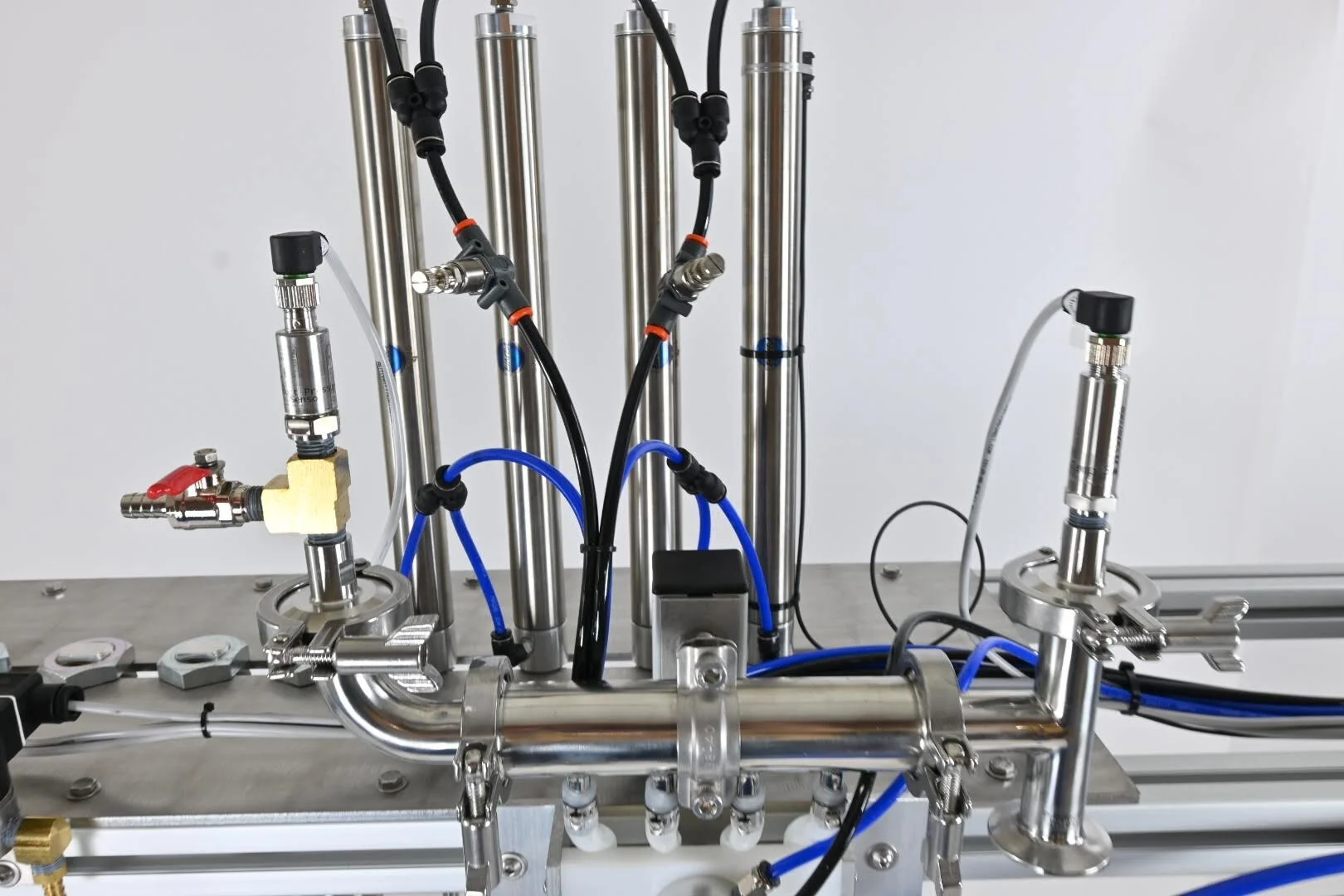

PLC CONTROLLED FOR ACCURACY

Automatically purges with CO2 and Counter Pressure prior to filling

Automatically fills and self-levels to the correct fill height.

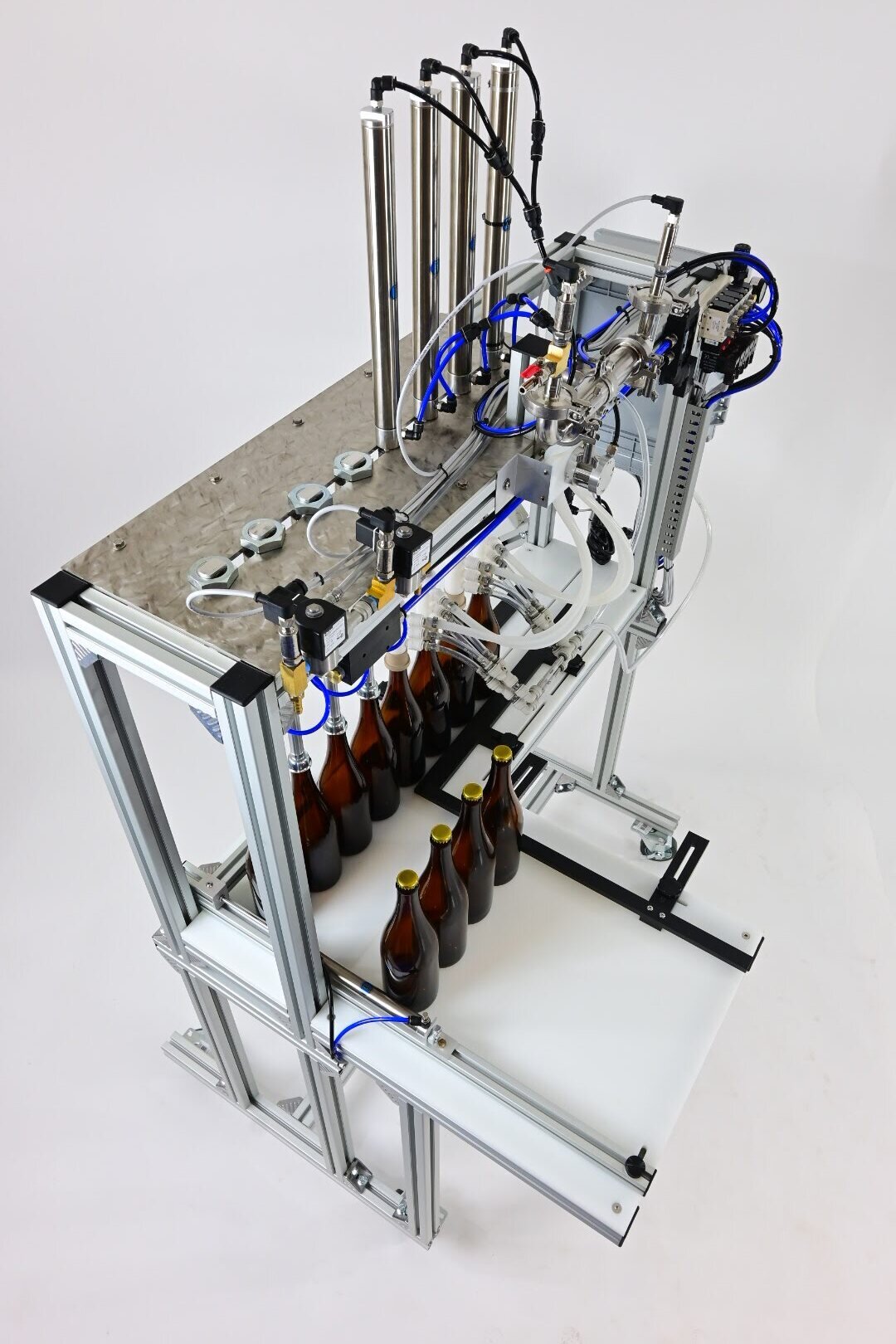

Glass advances between fill heads and crowners for bottle capping,

Temperature and Pressure sensing with on screen readout

Pushes bottles on to Pack off Table (4-head filler)

TOUCH SCREEN INTERFACE STANDARD

Adjustable fill cycle and purge timing

CIP (clean in place)

Crowner

OPERATOR CONTROLLED

Start & Stop

Loading and unloading glass on and off of filler.

Loading crowns onto crown heads for capping.

FILL RATES

Fill rates are influenced by product temperature and product carbonation levels.

6-8 bpm (2-head filler)

12-16 bpm (4-head filler)

System Requirements

Compressed CO2

5 cfm @ 90 PSI air supply (2-head filler)

11.5 cfm @ 90 PSI air supply (4-head filler)

120V or 220V 1PH (2- and 4-head fillers)